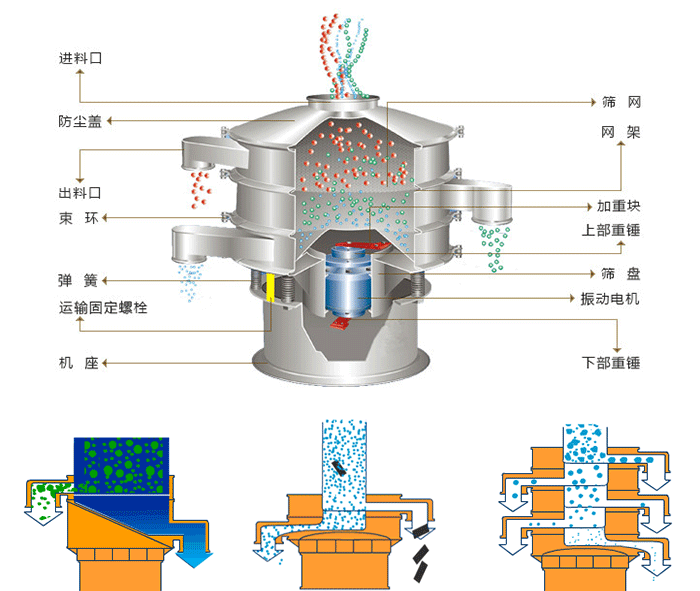

The rotary vibrating screen is widely used in the screening of finely crushed powder or granular materials due to its high precision, non clogging mesh, good airtightness and other advantages. In the use of rotary vibrating screen, the role of eccentric block cannot be ignored. It is precisely because of the phase angle formed by two eccentric blocks that the screen machine can work normally.

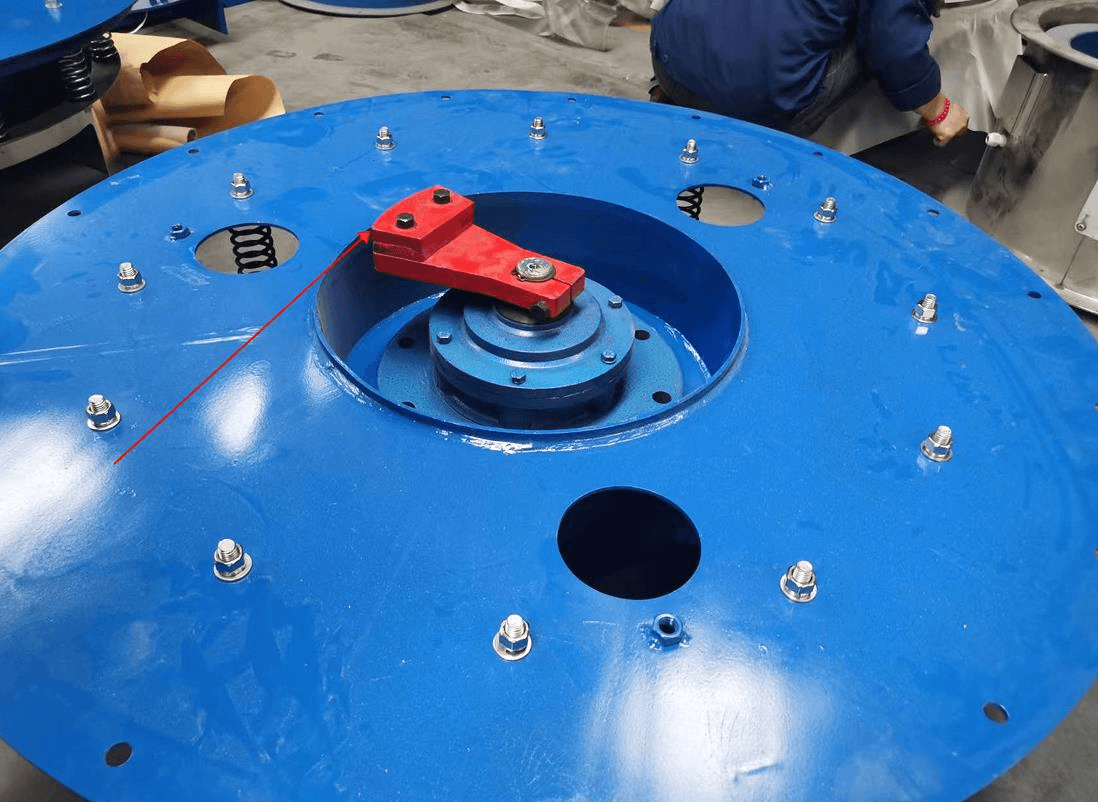

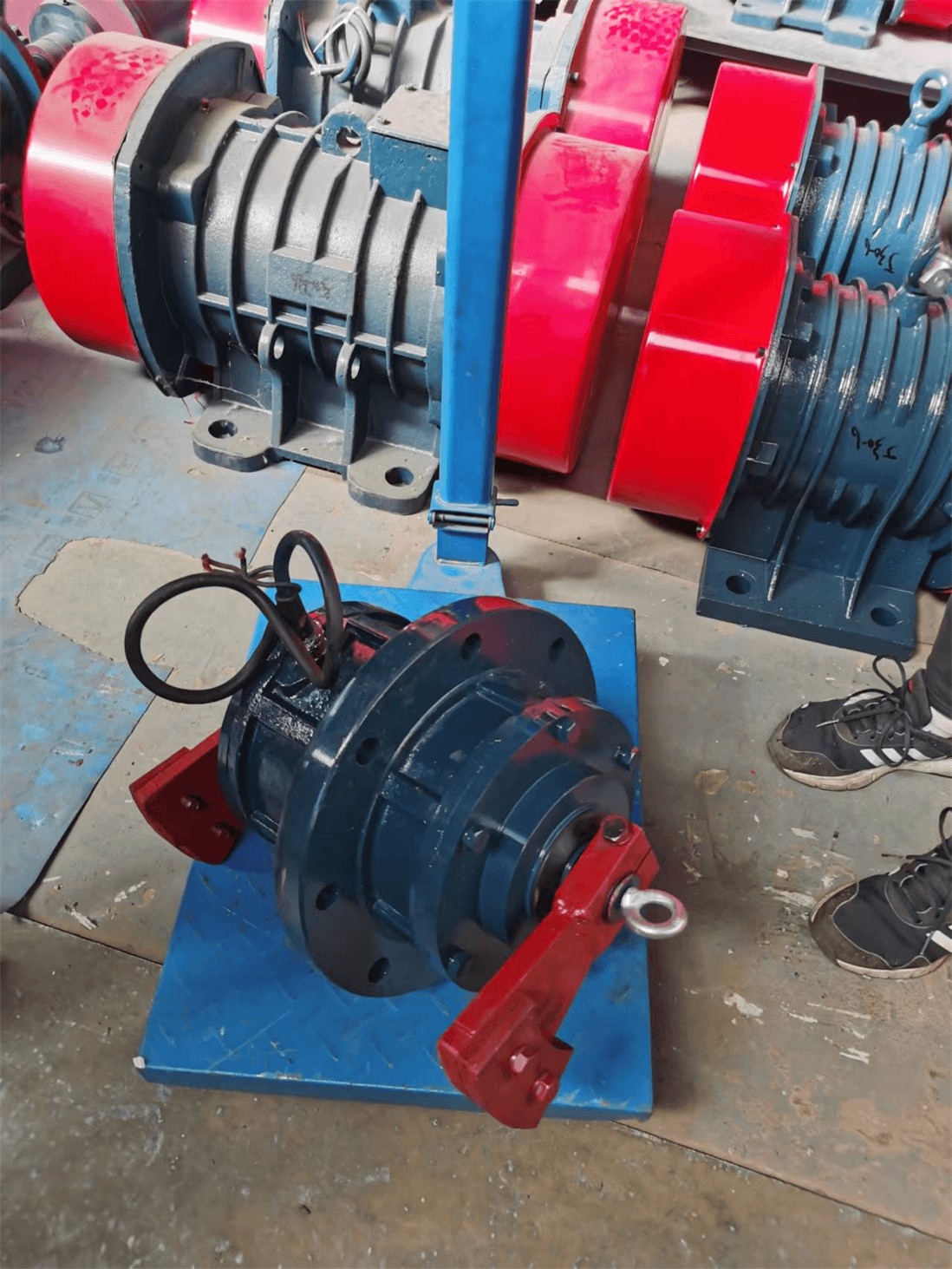

The eccentric block adjustment method:

1,We can adjust the additional weight of the vibrating motor. The additional weight is installed on one side of the upper and lower weights (upper and lower eccentric blocks), which can increase the exciting force of the vibrating screen. According to the specific gravity of the materials to be screened and the number of layers of the vibrating screen selected by the customer, the number of counterweights can be appropriately increased and reduced.

2,Open the adjusting hole of the bottom barrel of the vibrating motor of the rotary vibrating screen, loosen the fixing bolts of the eccentric block, adjust the upper and lower angles of the upper and lower eccentric blocks in the opposite direction to the discharge port according to the track of the screened materials, and then put a small amount of materials on the screen surface to make the screen machine run and check the running track of the materials on the screen surface. If the angle adjusted reaches the required level, you can stop the machine and tighten the fixing bolts of the eccentric block.

3. When the vibrating screen starts to work, the screening is continuous, and the vibration amplitude is relatively large during rough startup and shutdown. If you want to reduce the amplitude, you need to reduce the angle of the eccentric block. However, if the adjustment is too small, the equipment will have no strength.

4. The coarse screening requires a higher output of the screen, which is more suitable for the situation where the powder contains large particles or less impurities. The angle of the eccentric block of the rotary screen is generally within the range of 30 °. Therefore, when the screening accuracy is not required, but the output is required, the angle of the eccentric block can be 0-30 °.

Post time: Jan-04-2023